24 May Marangoni unveil groundbreaking new equipment and process for medium-size retreaders

Revolutionary High Efficiency, Breakthrough Reduced costs with Marangoni’s Intuitive and environmentally friendly RingBuilder Saturn

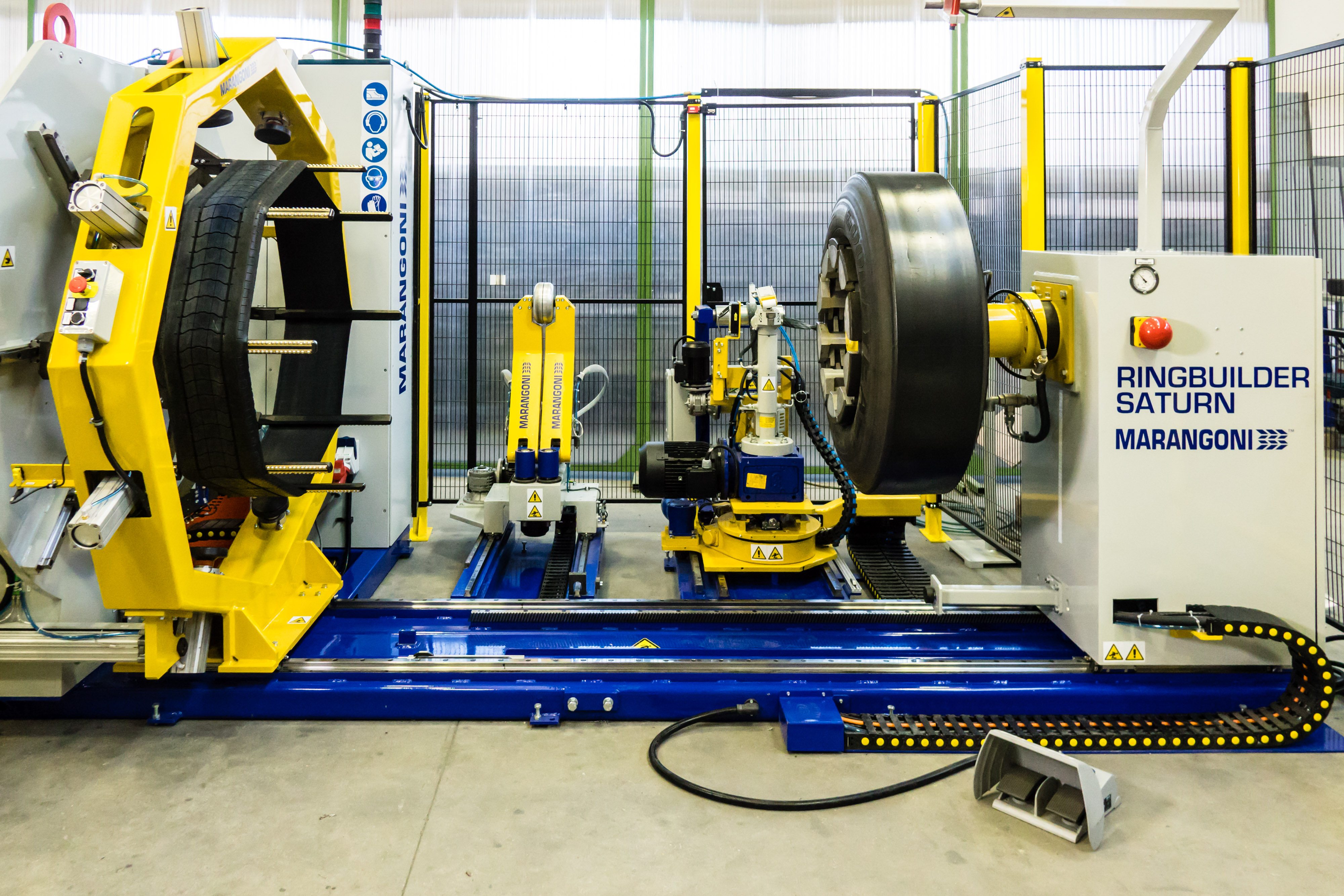

Rovereto (IT) – Marangoni Retreading Systems recently introduced their most cost effective retreading system ever with the worldwide launch of the unique Ringbuilder Saturn, an exclusive new technology guaranteeing outstanding tyre-level performance and exceptional value for money.

The product builds on the proven success of the 70-year-old Italian company’s RINGTREAD System, and is a major upgrade on their tried and tested RT1000S Ringtread-builder and Black Swan cushion-gum Extruder systems, which have already enjoyed global success in the marketplace.

The RingBuilder Saturn is the next generation of machineries to facilitate use of market leader Marangoni’s cold retreading technology RINGTREAD System, which utilises splice-less precured tread rings, perfect adhesion, and offers an accessible 10 tyre an hour capacity at much lower prices than its “bigger sister” Ringbuilder 3003.

It is the first machine to be brought to the market by Marangoni as part of the company’s new strategy to satisfy price-conscious medium size retreaders with less need for automation.

The RingBuilder Saturn 3000 is capable of producing up to 80 tyres per eight hour shift, and is a more environmentally friendly alternative to the company’s existing RingBuilder 3003 system, at a much lower price.

Its’ easy to use operating system allows the user to apply a thin, overlapping strip of extruded cushion gum during multiple rotations on to the crown and shoulder of a tyre-casing. This strip size cushion, while is not totally eliminating the need to fill larger craters, permits a reduced and precise application of the right quantity of cushion-gum. The RingBuilder Saturn then applies a pre-cured tread-ring on the casing – all during the same build-cycle, and without any need to shift the tyre during the process.

The first installation of the new technology occured in Lourosa, Portugal, at the Lusitania Paulino e Gomes retreading plant. Mr Antonio Cruz, Director of Lusitania Paulino e Gomes retreading company declared a few weeks after the commissioning of their Ringbuilder Saturn: “I am very happy about the productivity of this machine, today with one operator only we produce the same quantity than before with two. The technical quality of the retreads is excellent and the footprint of the machine is compact. The human-machine interface is intuitive, it makes its functioning really easy for any new operator”.

Rovereto, 24.05.2017

NOTE TO EDITORS:

Marangoni Retreading Systems is the division of the Marangoni Group focused on the development and global distribution of systems, materials and technologies for the cold retreading of commercial tyres.

Marangoni Retreading Systems offer an integrated system of products and services providing the tools and know-how needed to ensure efficient retreading processes, high quality products, and world class service and support to optimise commercial activity.